Keyboard Hacking.

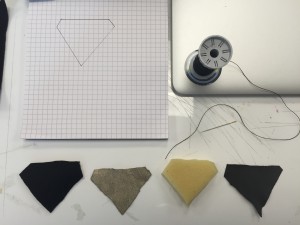

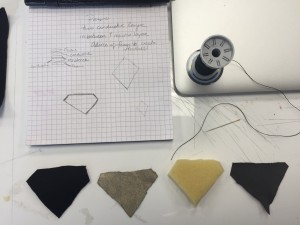

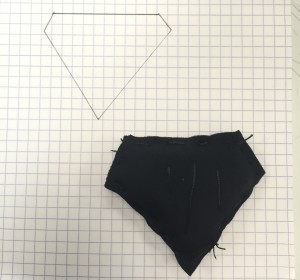

My original idea for this hack was to create something that enhanced the experience of cooking while using an online recipe without getting food all over your laptop. My idea was to use a thin plastic plate that is easy to clean and of course can endure flour, sauce – you name it!

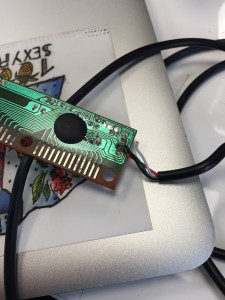

Step 1. Unscrew you keyboard and find the pcb controller and remove it from the keyboard. Then you want to gently sand the silver keys. Be careful not to sand off too much!

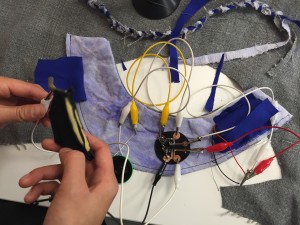

Step 2. Connect the pcb controller to a computer and begin searching for usable keys.

Step 3. Solder wires on the key combination you would like to emulate.

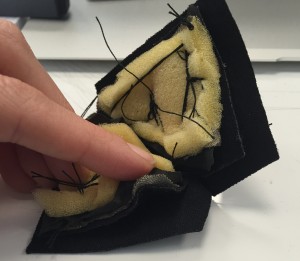

Step 4. Connect this to an object you would like to use to control the key combination chosen.

Unfortunately after connecting my wires to the key combination I had found, which in this case it was the space key which would allow you to navigate down the recipe page, the delicate pcb controller wires disconnected.

After multiple failed attempts of re-soldering the pcb connectors I was feeling quite defeated.